同创自成立以来,始终专注于技术研发和创新,拥有一支深耕钕铁硼行业近30年的高水平研发团队。以市场和客户需求为导向,以 NIMTE(中国科学院)和博士后工作站为后盾,以专业的工程技术人员为前哨,为客户提供永磁行业的前瞻性咨询和建议,协助客户改进磁路设计,解决磁体使用过程中遇到的问题, 并提供最具性价比的永磁产品,以最大限度地提高磁体的效率。

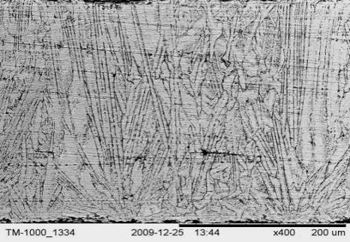

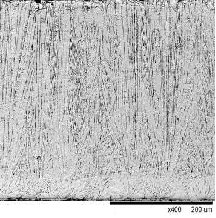

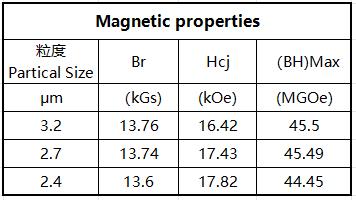

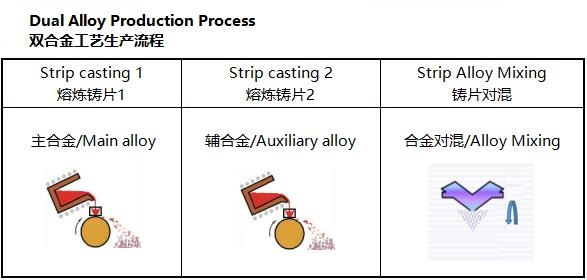

含铈钕铁硼磁铁是指在钕铁硼钕铁硼磁铁的配方中添加高丰度稀土元素(镧La、铈Ce),减少镨钕的用量,达到降低成本的目的。

分子式:Nd2Fe14B(Ce2Fe14B,RE2Fe14B)

近年来,公司开发了一系列高丰度稀土磁铁品牌产品。在应用方面,它突破了高丰度稀土磁铁集中在低端领域的局限性,如电动滑板车、箱包扣、门扣、玩具等。

典型应用: 两轮或三轮电动车电机

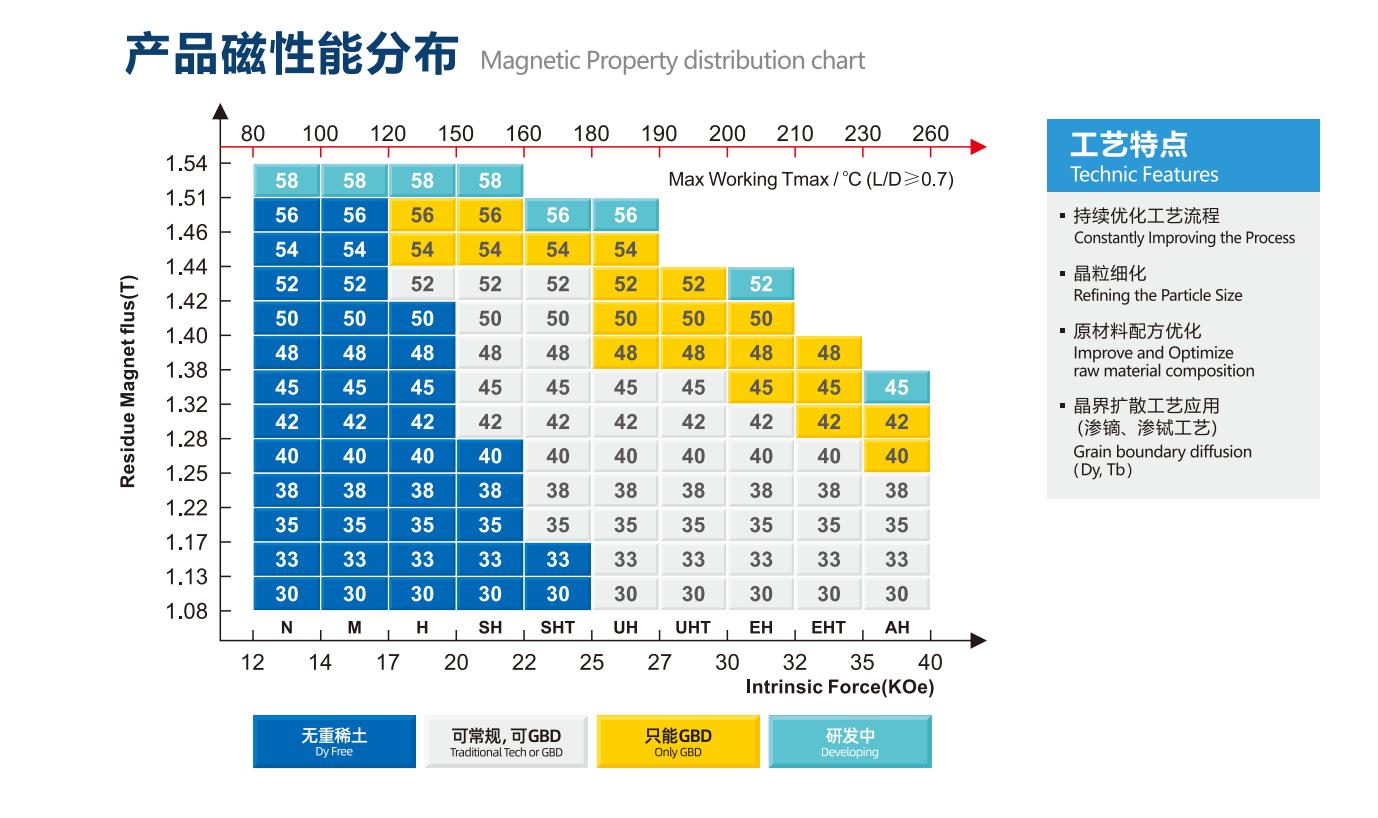

永磁体,也称为永磁体,可以是天然产品或人工制造的(最强的磁铁是钕铁硼磁铁)。一种具有宽磁滞回线、高矫顽力 Hcj 和高剩磁 Br 的材料,磁化后可以保持恒定的磁性。 在应用中,永磁体在深度磁饱和和磁化后,在磁滞回线第二象限的退磁部分工作。永磁体应具有尽可能高的矫顽力 Hc、剩磁 Br 和最大磁能积 (BH) max,以确保磁能的最大储存和稳定的磁性。

凭借丰富的制造经验和先进的设备,同创为磁性产品的设计、仿真、原型制作和优化提供完整的工程支持,不断改进磁性材料的功能并将其集成到提供的产品中

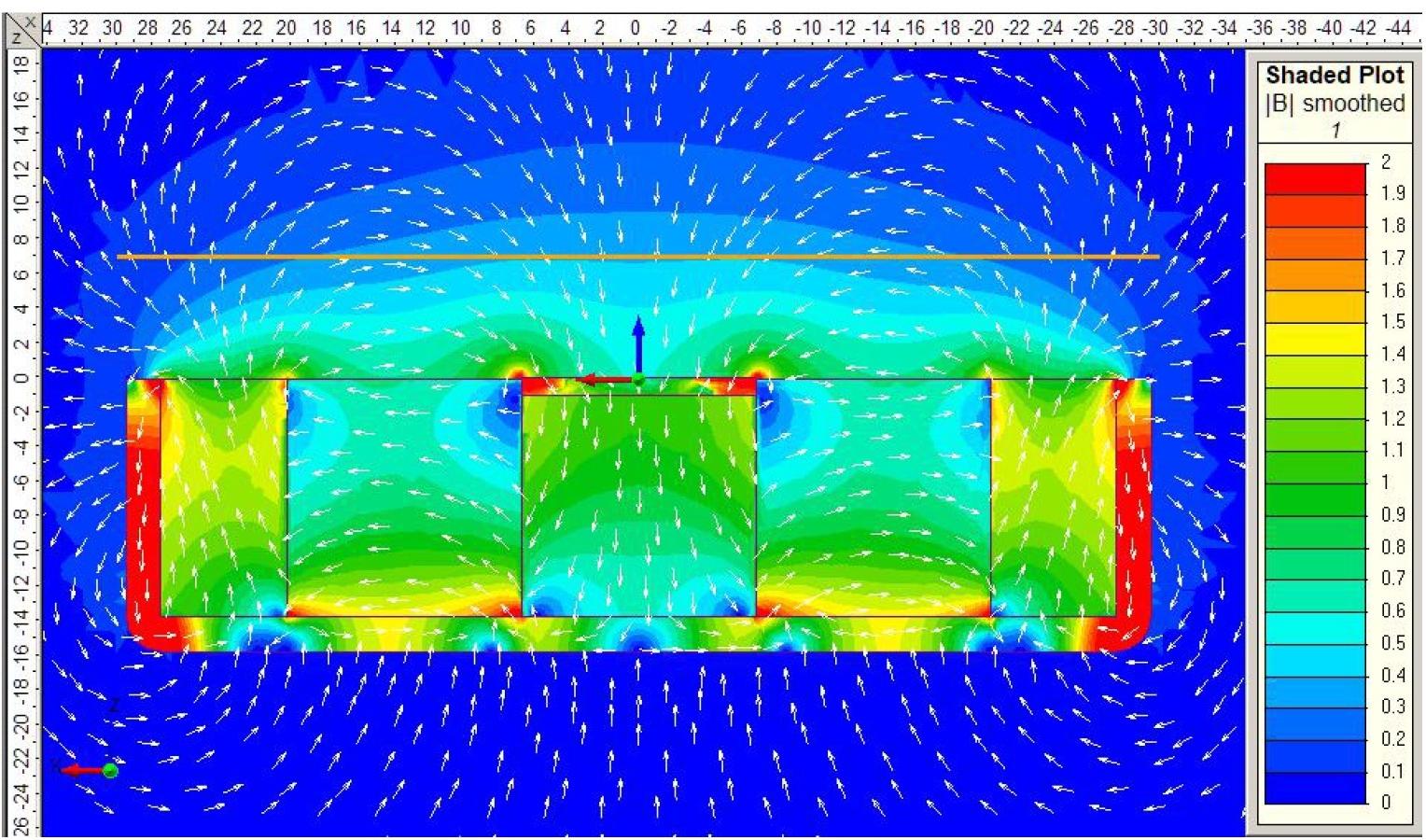

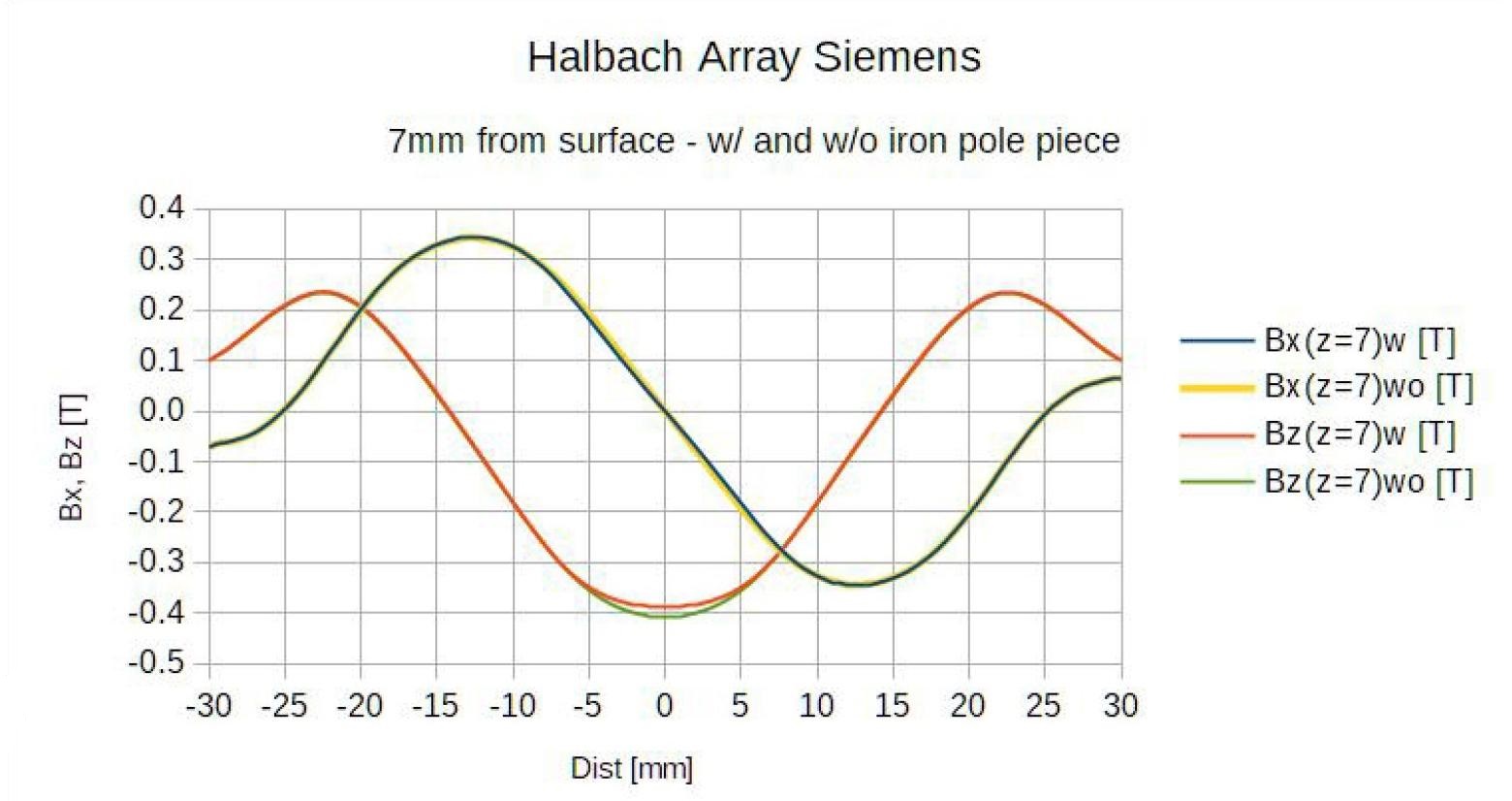

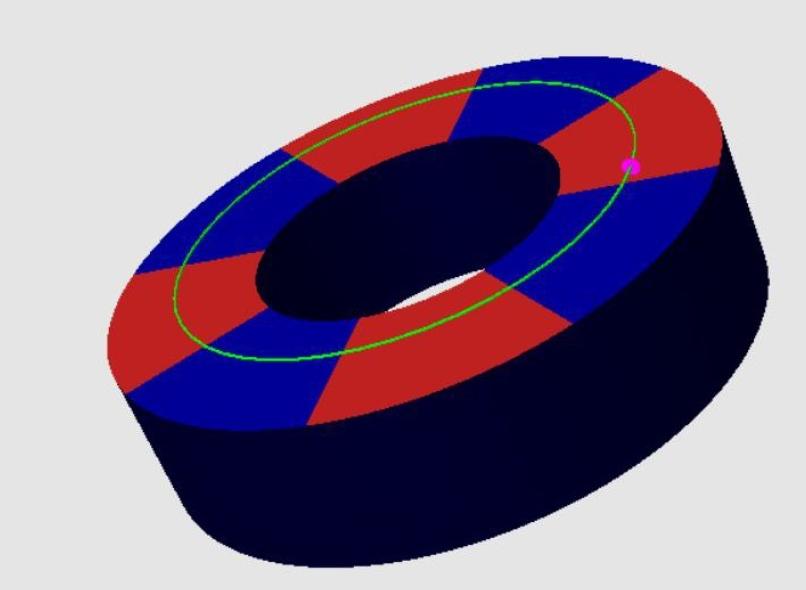

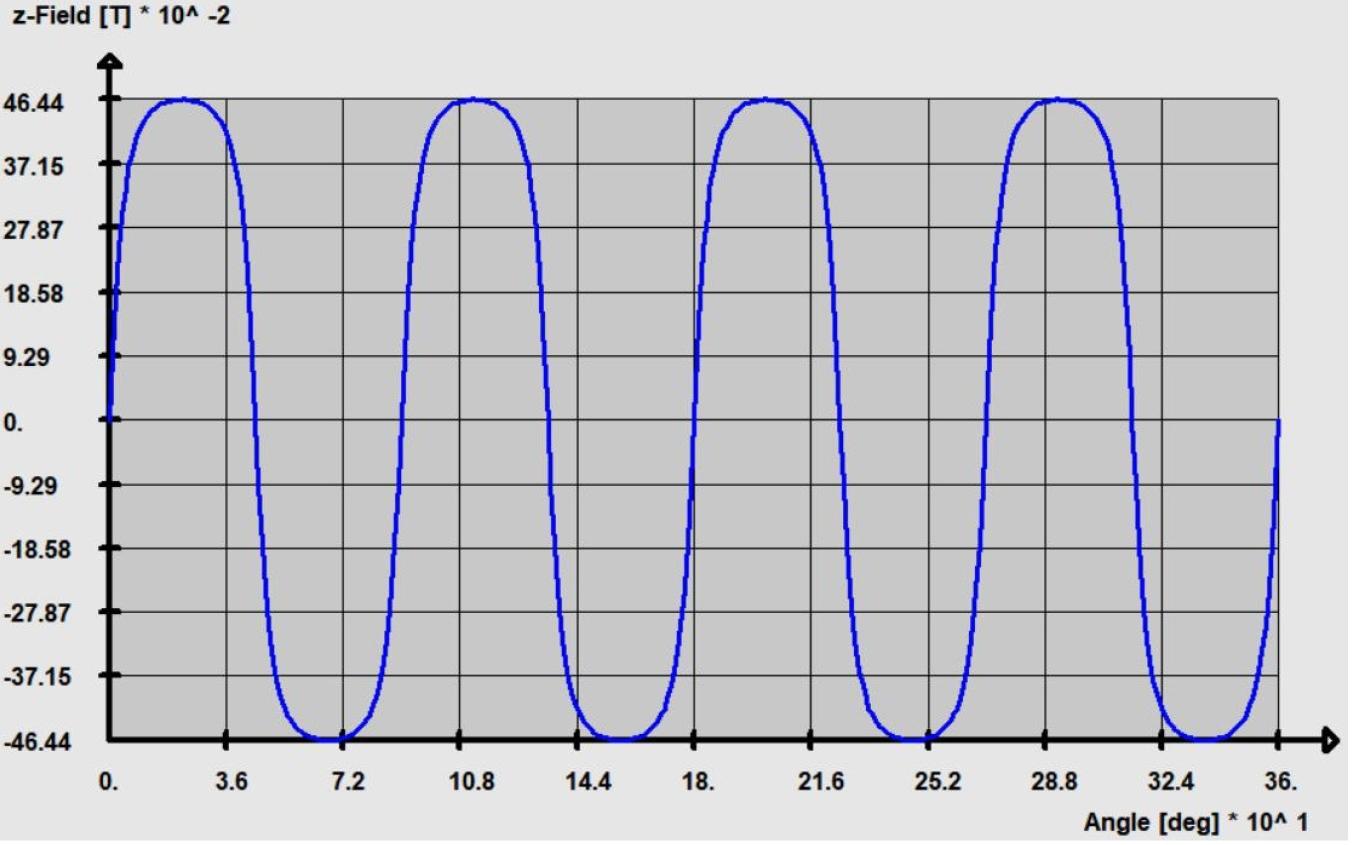

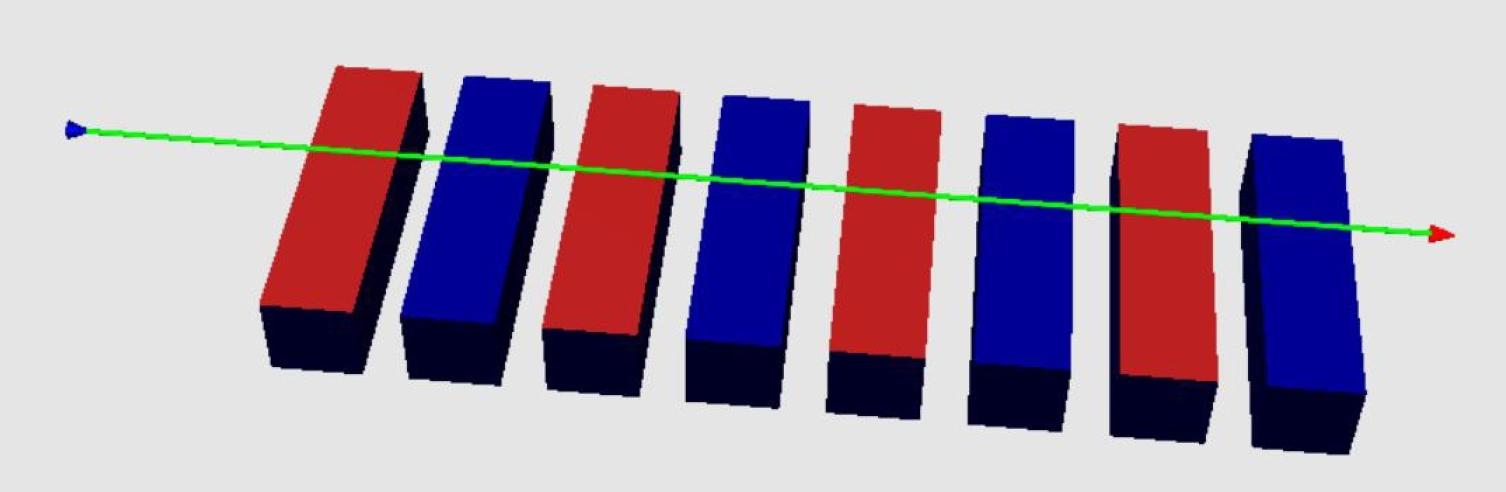

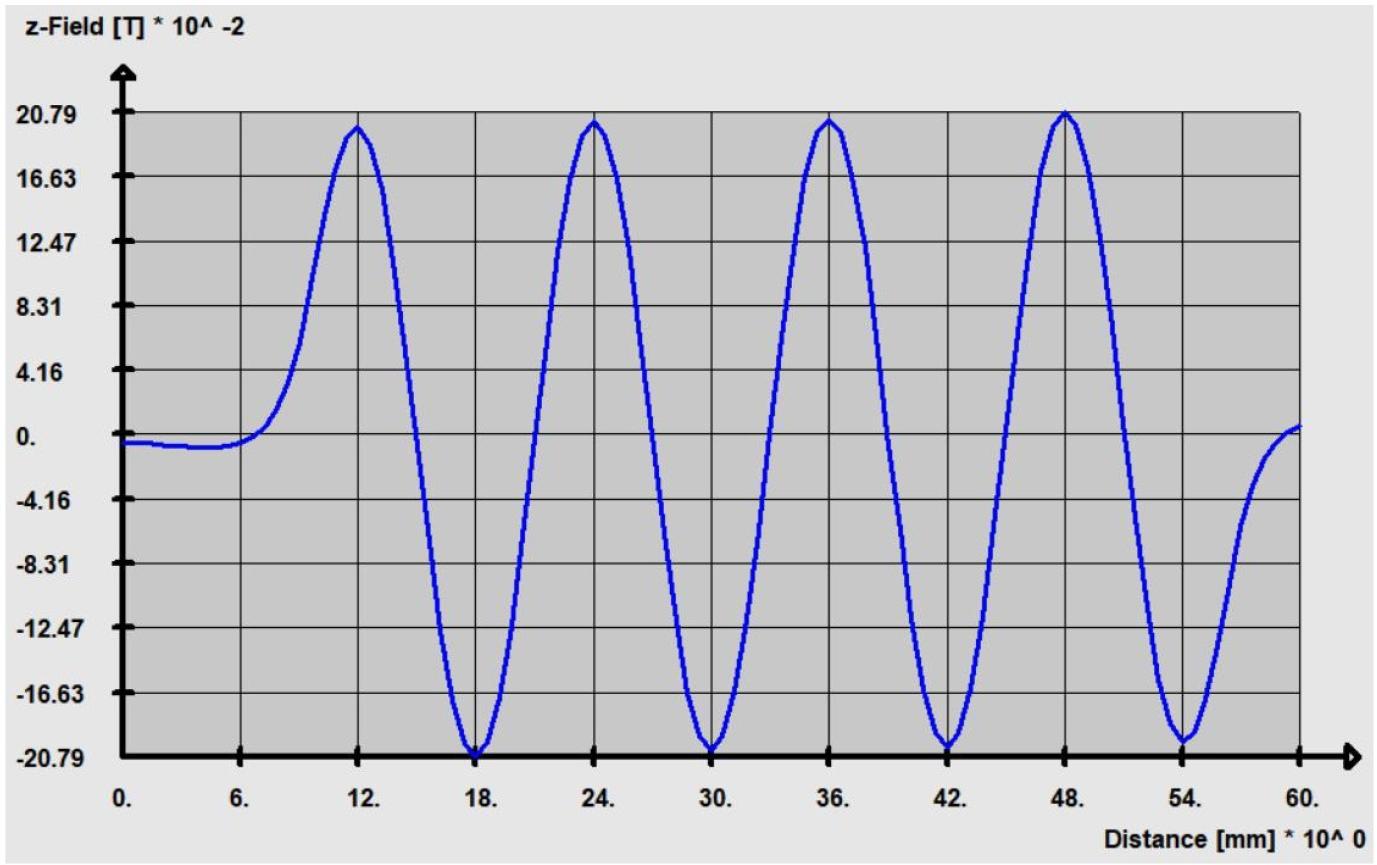

TC 具有 2D 和 3D 有限元分析 (FEA) 建模功能,可分析磁性元件和组件;并且我们可以使用Maxwell的磁方程设计进行计算机模拟,以帮助磁铁用户计算磁力并选择合适的磁铁。

磁性元件跟踪产品应用

传感器磁铁

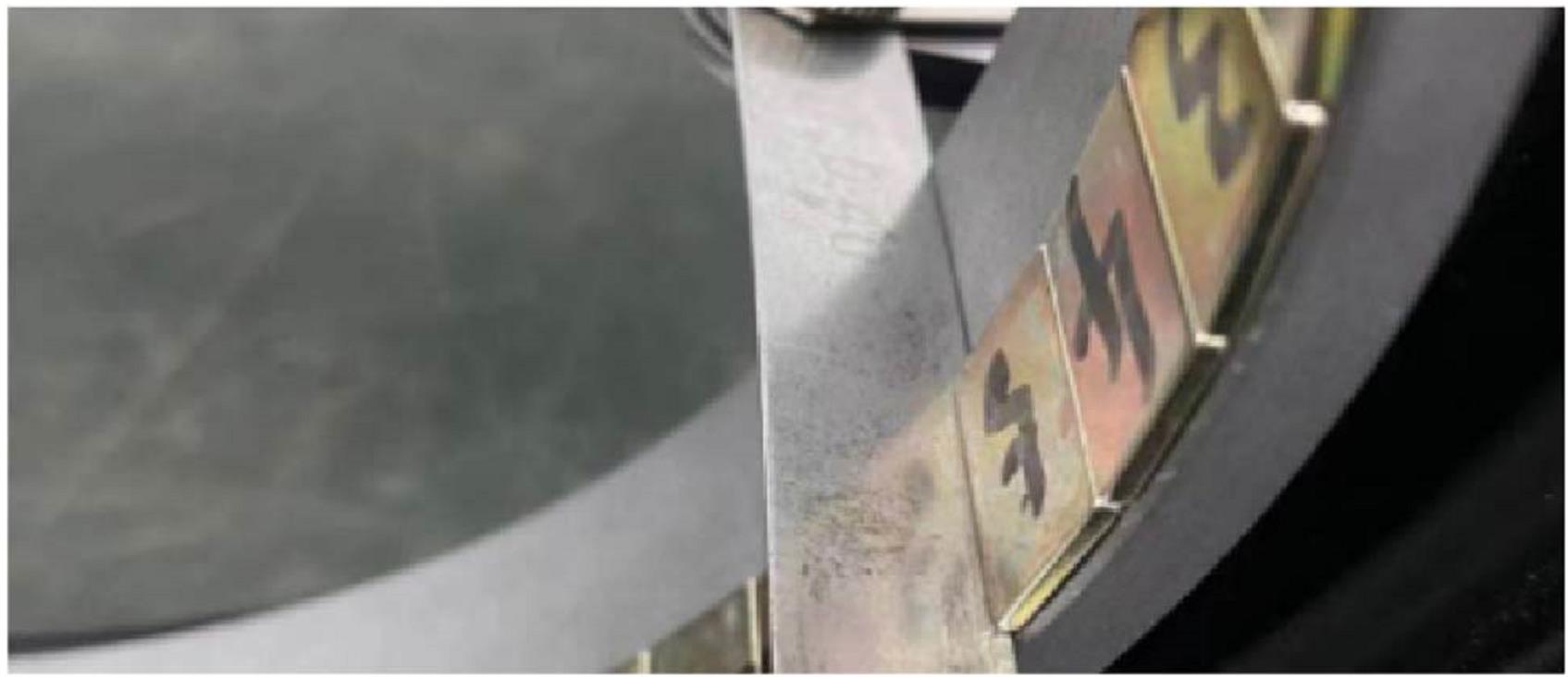

直线电机磁铁

大型Halbach阵列